Arc flash events don’t happen every day but when they do, the outcome can be catastrophic. In an instant, equipment is destroyed, operations are halted, and lives are put at risk. Yet despite the severity, many organizations still hold outdated or incomplete beliefs about what an arc flash study entails.

And that’s a problem. Misunderstanding arc flash study requirements often leads to bare-minimum compliance, outdated documentation, and dangerous gaps in protection. At Bowtie Engineering, we’ve seen firsthand how quickly these misconceptions turn into liability. This article aims to clear the air so you can protect your people, your equipment, and your uptime.

One-Time Study? Think Again

One of the most common myths is that an arc flash study is something you do once, check off the list, and forget. The reality couldn’t be further from the truth.

Arc flash study requirements, per NFPA 70E and OSHA 1910, are clear: these studies must be reviewed at least every five years or whenever significant system changes occur. And let’s be honest, electrical systems rarely sit still. Upgrades, new machinery, reconfigured panels, and even environmental changes can impact incident energy levels.

That’s why Bowtie approaches each study as a living asset. Our BowVue® system tracks equipment, labels, and risk levels across your facility, keeping your arc flash documentation aligned with your actual infrastructure.

When you view your study as a dynamic tool—not a static report—it starts to work for you, not just for your compliance binder.

Only for Big Facilities? Not Even Close

Another misconception: arc flash studies are only necessary for large, complex facilities. Small commercial buildings, retail locations, and even boutique manufacturing sites sometimes assume they’re too minor to warrant a full analysis.

That logic is flawed. The energy available in an arc event doesn’t scale with square footage. It’s about the equipment, the fault current, and the clearing time. A single energized panel in a small space can still pose a deadly risk. OSHA data and industry reports estimate that 5 to 10 arc flash incidents occur daily in the U.S., affecting facilities of all sizes.

OSHA doesn’t offer exemptions based on building size; the standard applies universally. If your facility has employees working on or near energized systems over 50 volts, arc flash study requirements apply to you. Bowtie regularly works with small and mid-size clients whose risks are just as real, and whose protection matters just as much.

Compliance Isn’t the Finish Line

There’s a dangerous assumption that being “compliant” is the same as being “safe.” While meeting arc flash study requirements is essential, it doesn’t guarantee your team is protected or even informed.

Too many studies end with a folder of labels and a spreadsheet of values. No interpretation, no walkthrough, no conversation about what those numbers mean for daily operations. Without context and follow-up, those results sit unused, gathering dust while real hazards persist.

At Bowtie, we take a systems-focused approach. That means clear explanations, actionable findings, and integration with existing safety programs. We also conduct thorough arc flash training to ensure your personnel understand how to interpret the study and apply it in the field.

A proper study should lead to understanding, not confusion.

PPE Isn’t a Shortcut to Safety

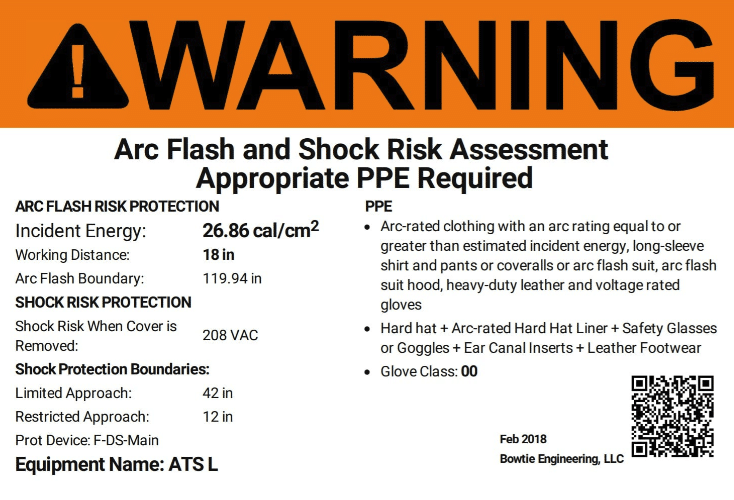

Personal Protective Equipment (PPE) is vital. But it’s not a silver bullet. Without the right information backing it—accurate labeling, updated incident energy calculations, and hazard awareness—it can easily give a false sense of security.

Over-relying on PPE without validating system conditions leads to dangerous missteps. If the gear doesn’t match the actual arc energy levels present, it may not offer the protection it promises. Worse, it might embolden workers to take unnecessary risks, assuming they’re covered.

That’s why arc flash training and accurate system data must go hand-in-hand. At Bowtie, we focus on aligning all three: analysis, protective equipment, and human behavior. The goal isn’t just avoiding citations; it’s enabling safe work, every single time.

Not All Studies Are Created Equal

Let’s be blunt: there’s a wide range in quality when it comes to arc flash studies. Some are little more than software outputs, performed with minimal system knowledge or engagement. Others are deeply technical but lack accessibility for the people who actually need to use the information.

Bowtie’s method is structured, field-tested, and engineered for real-world use. Our six-step process goes beyond calculation; it’s about risk reduction, team empowerment, and long-term clarity. Our NFPA 70E-qualified experts provide site-specific labeling, explain the findings to your staff, and stay engaged long after the report is delivered.

In an industry where overgeneralization can cost lives, specificity matters. So does a trusted partner who takes ownership alongside you.

Changing the Way You Think About Safety

Misconceptions don’t just come from inexperience. They’re often the byproduct of rushing to meet minimum standards. But facilities that thrive in today’s environment understand that safety is a system, not a checkbox.

Arc flash study requirements aren’t about bureaucracy. They’re about creating a safer, more informed workforce; about maintaining equipment that lasts longer and fails less; and about staying ahead of threats instead of responding to them after the fact.

When studies are treated as living documents and backed by proper arc flash training, they become part of a proactive safety culture, one that puts people and uptime first.

If it’s been more than five years since your last review, or if your study sits untouched in a drawer, it’s time to act. Bowtie Engineering will help you reassess, retrain, and refocus your arc flash strategy to reflect your real-world needs.

Reach out to Bowtie Engineering today to schedule a review or start your next study; we’ll make sure your team is prepared. Not just compliant.

Frequently Asked Questions

How often do arc flash study requirements need to be met?

According to NFPA 70E, updates are required every five years or after any significant system changes.

Is arc flash training mandatory?

Yes. OSHA and NFPA 70E both require training for employees exposed to electrical hazards. The training must be up to date and relevant to the tasks performed.

Can small businesses skip arc flash studies?

No. Facility size doesn’t change the obligation. If your team works on or near energized equipment, you need a study in place.

What’s included in proper arc flash training?

It should cover hazard awareness, PPE selection, interpreting labels, safe work practices, and response procedures—all based on your facility’s actual risks.

How do I know if my last study was done correctly?

If it didn’t include site-specific labeling, follow-up recommendations, or training, it may not be complete. Bowtie can help you evaluate its effectiveness.

What makes Bowtie’s arc flash studies different?

We go beyond the numbers. Our approach focuses on clarity, usability, and risk reduction; plus, we stay involved from study to implementation.

Skip to content

Skip to content