Arc flash incidents are sudden, violent, and incredibly destructive. In an instant, thermal energy from an arc flash can cause life-altering injuries and destroy critical electrical equipment. The consequences reach beyond lost productivity; they often impact lives, insurance claims, compliance status, and your bottom line.

That’s why arc flash hazard analysis isn’t just a safety protocol; it’s a strategic risk mitigation process that helps businesses identify, assess, and reduce electrical hazards before they result in serious incidents.

Key Takeaways

- Understand what arc flash analysis includes and why it’s a key part of any workplace safety strategy

- Learn how an incident energy analysis supports NFPA 70E and OSHA standards compliance

- See how PPE labels, boundary calculations, and system insights protect employees from electrical hazards

- Discover how Bowtie Engineering’s expertise leads to actionable reporting and reliable risk mitigation strategies

What Arc Flash Hazard Analysis Involves in an Electrical Safety Program

An arc flash hazard analysis is a structured process used to evaluate potential exposure to incident energy within a facility’s electrical systems. This analysis helps determine the likelihood and severity of an arc flash event at each point in the system.

Technicians perform calculations that factor in fault current, breaker settings, and equipment layout to measure incident energy levels. These results define boundary distances and required personal protective equipment for workers performing energized electrical work.

In addition to complying with NFPA 70E and OSHA regulations, this analysis lays the foundation for safe work practices and informed decision-making around risk.

Why Arc Flash Studies Are Critical for Risk Mitigation and Compliance

Every arc flash study is a critical risk assessment tool. When done right, it becomes a foundation for a risk mitigation plan that safeguards people and infrastructure. Left undone, you’re exposed to certain risks, including severe workplace injuries, operational shutdowns, regulatory citations, and insurance complications.

Electrical hazards are one of the top contributors to workplace injuries in industrial and commercial environments. Properly labeling equipment, defining risk levels, and assigning PPE requirements can dramatically reduce these risks. It also demonstrates to OSHA inspectors—and your insurance company—that you are actively working to reduce electrical hazards in a systematic, documented way.

In industries governed by strict compliance regulations, failing to comply with NFPA 70E can trigger fines, lost contracts, or liability exposure. Performing an incident energy analysis isn’t a formality; it’s a necessary safeguard for anyone responsible for workplace safety and operational continuity.

Bowtie Engineering’s Incident Energy Analysis and Risk Assessment Process

At Bowtie, our engineers follow a clear, consistent methodology that ensures accuracy and real-world value. Every project starts with a walkthrough to understand system layout, breaker coordination, and electrical equipment condition.

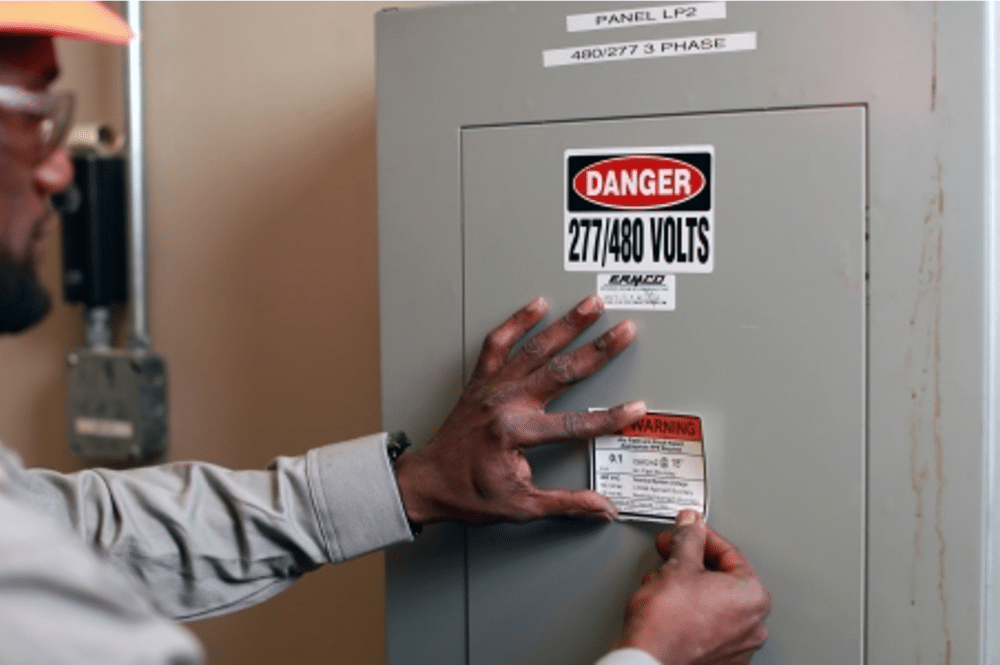

We then run a software-based incident energy analysis to model potential fault conditions. Based on this, we calculate incident energy levels, identify exposed hazards, and create customized arc flash labels that specify PPE, boundaries, and hazard categories.

Our studies are tailored for real-world implementation, giving business leaders and facility managers clear insight into risk mitigation, corrective actions, and resource allocation. We also provide training, support for administrative controls, and optional integration with BowVue for ongoing monitoring.

By aligning with national fire protection association standards and using experienced engineers, Bowtie helps companies comply with complex regulations while actively protecting their workers.

What Happens After the Study?

Once your analysis is complete, you’ll receive a comprehensive report with:

- Asset-specific arc flash labels with PPE categories

- Updated risk levels for each panel or component

- Documentation that meets NFPA 70E and OSHA standards

- Clear next steps to improve workplace safety and equipment reliability

- Options for additional risk mitigation strategies or system upgrades

You’ll also be better equipped to implement risk avoidance practices and understand where risk acceptance may or may not be appropriate.

For facilities seeking to limit setbacks or ensure continuity, this is an important step in a broader risk management plan.

The Smarter Way to Protect What Powers Your Business

You can’t eliminate every hazard, but you can identify, plan for, and significantly reduce the possibility of an arc flash incident. That’s what risk mitigation strategies are built to do.

Through Bowtie Engineering’s arc flash studies, you gain more than compliance; you gain clarity. Your team is safer, your equipment lasts longer, and your operation is better protected against disruptions that don’t always come with a warning.

Ready to take the next step in protecting your people and infrastructure? Request your arc flash hazard analysis today.

Frequently Asked Questions

What is arc flash hazard analysis?

It’s a process that evaluates electrical systems to determine incident energy levels at potential fault points, identifying risks and assigning PPE to protect workers. Contact us to schedule a study or get a free risk consultation.

How often is arc flash analysis required?

Every five years or after major electrical changes. This keeps your risk mitigation plan current and ensures you’re aligned with NFPA 70E compliance requirements.

What’s included in the final report?

Our analysis provides equipment labels, PPE designations, boundary distances, and detailed notes to support safe work practices and training.

Why do OSHA and insurance carriers care about arc flash studies?

OSHA enforces NFPA 70E standards, and insurance companies often require documentation for liability purposes. A current study shows you’re taking active steps to reduce risk.Can Bowtie assist with post-analysis action plans?

Absolutely. We help implement label updates, provide PPE recommendations, and offer safety training aligned with the analysis.

Skip to content

Skip to content